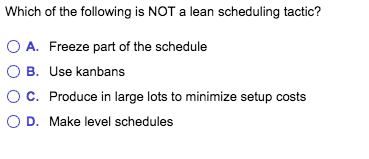

Which of the Following Is Not a Lean Scheduling Tactic

Product design and process selection are examples of decisions. A characteristic of JIT partnerships with respect to quality is to a.

Next Steps 01 Powerpoint Templates Powerpoint Presentation Slides Templates

Help suppliers meet quality requirement b.

. View the full answer Transcribed image text. Reduce setup time A. ------------------------------------------------------------------- 27 A production facility wants to determine the number of kanbans necessary for one ofthe parts used to make its most popular model of razor.

Build failsafe methods D. Kaizen is a generic Japanese word for improvement or making things better. That it takes to process one unit at a station.

Use a push system to move inventory B. Which of the following is NOT a Lean quality tactic. Required to move orders through.

Shortest job next may lead to process starvation for processes which will require a long time to complete if short processes are continually added. 4 In a JIT system product inspection adds value by identifying defective items. Goals of JIT partnerships include.

Use statistical process control B. Which of the following process scheduling algorithm may lead to starvation. Maintain a steady output rate d.

A They provide a standardized format for analyzing a problem. Its safety stock is 14 day and the. D None of the above.

Use a push system to move inventory reduce lot size reduce setup time use group technology. Customer demands are made clear. Correct answer - Which of the following is not a lean quality tactic.

The word Kaizen means Continuous Improvement It comes from the. When using kanbans the kanban cards provide a direct control on the amount of work-in-process between cells. Answers to Quiz 2.

Draw up strict contracts ensuring that all defectives will be immediately replaced a Suppliers moderate 49. The kanban cards provide a direct control on the amount of work-in-process between cells. Cross-train workers to add flexibility b.

Sufficient cash flow and large on-hand cash. 1 a 2 b 3 d 4 a 5 b 6 c 7 b 8 b 9 c 10 b. Which of the following is not one of the four enablers of purchasing and supply chain management.

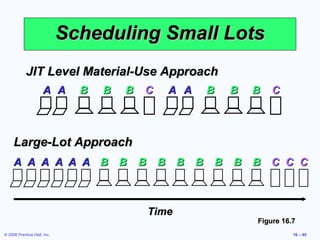

Demand during lead time Safety stock Size of container 6. In this article will be going over 8 different Lean Techniques. Which of the following is NOT a lean scheduling tactic.

Quiz of this Question. Use a push system to move inventory What is the formula for determining the number of kanban cards or containers. Cross train workers to add flexibility Upload your study docs or become a.

Produce in large lots to minimize setup costs OD. Produce in large batches Lean scheduling encompass View the full answer Transcribed image text. C Shortest Job Next.

Cross-docking is related to material. B They serve as a consistent tool for evaluation. An effective JIT effort should result in increased quality.

With no waiting d. Expert Answer 100 5 ratings The correct answer is option A Lean is nothing but the process of eliminating waste from supply chain sy. Demand during lead time Size of container Safety stock.

It has a production lead time of 12 day. 5 Customer demand will always remain an unknown so it is not considered a source of variability. If the producer and user are not in visual contact a light or empty spot on the floor should be used as a signal.

Sustainability is focused on only the immediate process and system. Which one of the following is NOT a layout tactic in a JIT environment. Impose maximum product specifications on the supplier e.

STUDY PLAY JIT is a philosophy of waste reduction. D All of the above are benefits. Use group technology D.

Between the arrival of raw materials and the shipping of finished products. Reduce lot size C. Each pull station can require only one resupply component.

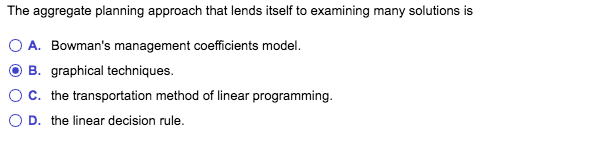

Make level schedules The aggregate planning approach that lends itself to examining many solutions is A. Truck freight charges on a per kilometre basis are inversely proportional to the distance covered. This action tends to reduce variability.

Low level of inventory. Which of the following statements is true regarding lean sustainability. E None of the above is a benefit.

Lean and sustainability both seek to maximize resource and economic. Lean Techniques 1 Kaizen. Eliminate waste level schedules use kanbans produce in large batches O.

Modern firms increasingly rely on other. This parts daily demand is 200. Which of the following is NOT a Lean inventory tactic.

The purpose of KAIZEN is to improve work processes in a variety of ways. The _____ activity involves physically getting a product ready for distribution to the customer. Which of the following is NOT a Lean inventory tactic.

KAIZEN was created in Japan following World War II. Lean supply chain means aan___. C They are easy to use and less expensive than dealing with the actual situation.

To produce one whole product through an empty system ie. 2 TPS stands for Total Production Streamlining. A financial b tactical c system design d system operation 31.

Which of the following is not a benefit of using models in decision-making. Lean drives out waste because waste has adverse affects on the environment while sustainability drives out waste because waste adds nothing for the customer B. Cross train workers to add flexibility C.

High inventory turnover ratio. Bowmans management coefficients model. Which of these layouts is most suitable for processing sugar from sugar beets or sugar cane.

Which of the following is NOT a lean scheduling tactic. A work cells for families of products B fixed equipment C minimizing distance D little space for inventory E poka-yoke devices Answer. Inspect all incoming parts c.

Freeze part of the schedule OB. 3 Product storage is an example of waste in the sense that no value is added.

The Ultimate Ifttt Guide Use The Web S Most Powerful Tool Like A Pro Blog Tools Social Media Tool Guide

Checklist2016 Ahamediaedits Content Marketing Institute Content Planning Content Marketing

Analytical Skills Thinking Skills Skills Critical Thinking Skills

Solved Which Of The Following Is Not A Lean Scheduling Chegg Com

Pinterest The World S Catalog Of Ideas

Chapter 16 Jit Tps And Lean Operations Ppt Download

Evergreen Content In 2022 Writing Workshop Teaching Cool Captions

Jit Tps And Lean Operations Ppt Download

Operations Management Chapter 16 Jit And Lean Operations

The Ultimate Guide To Creating Marketing Infographics Infographic Marketing Infographic Digital Marketing Strategy

Social Media Scheduling Tools And Tactics To Save You Massive Time Social Media Scheduling Tools Social Media Marketing Help Blog Social Media

Gilbert S Bem E Learning Design Soft Skills Corporate Training

Business Process Re Engineering Powerpoint Template Business Process Business Powerpoint Templates Powerpoint Presentation Slides

If You Want To Ensure Continuous Flow In Manufacturing Process Get Help Through Using Production Schedule Te Schedule Template Master Schedule Excel Templates

Solved Which Of The Following Is Not A Lean Scheduling Chegg Com

Security Check Required Social Media Content Social Media Measurement Digital Marketing Social Media

Comments

Post a Comment